Drilling Mud Treatment – Water and Oil Based Muds – Friction Reducer Sales

Lower water and waste disposal/transportation costs. Process on-site and recycle water for make up water Emulsion Breakers, Acids, Surfactants, Flocculants and Coagulants

Drilling Mud Recycling

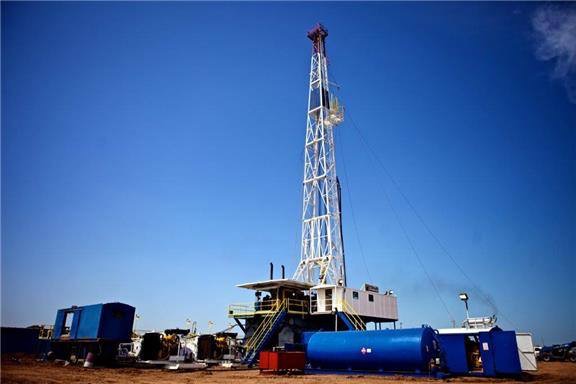

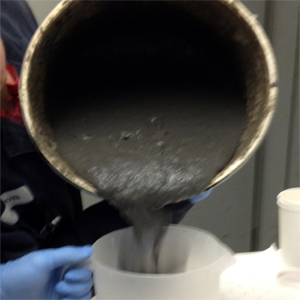

Water based and oil based drilling mud as well as waste cuttings from the solids control equipment can be broken down and processed on site or off site. The mud is broken down to release the water which is recovered and pH adjusted for disposal or reuse as make up water. The residual solids are then squeezed to remove as much water as possible reducing the volume of waste for disposal.

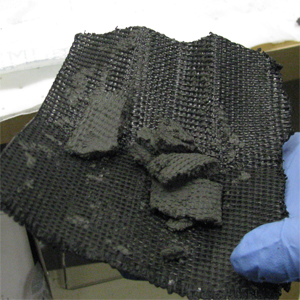

Many efficiencies can be instituted at progressive stages of the drilling mud circulation cycle. Solids control begins at the shaker where are solids are still coated with drilling mud. The cuttings can be washed and dewatered to remove residual contaminates making disposal less costly. The second stage of solids control is the centrifuge where the ports can be adjusted to remove more solids (wetter) solids discharge which is better for cleaning the drilling mud. The third stage is mud cleaners (hydro cyclones, desanders and desilters) where the underflow solids can be mixed with the centrifuge solids if applicable and dewatered to a semi-powder state. Each of these processes have residual clean water for reuse and or disposal. In some areas the residual solids can have a beneficial use in cement or road base applications.

Leave A Comment

You must be logged in to post a comment.